METALLURGICAL ANALYSIS CENTER

METALLURGICAL ANALYSIS CENTER

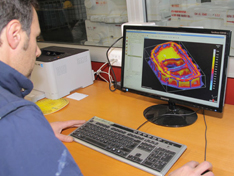

Founded over 30 years ago to support the cast iron foundry, in 2012 the laboratory was renovated with the most modern equipment for testing, analysis and simulation.

The Metallurgical Analysis Center improved the functionality for testing the mechanical and structural features of metals.

In addition to an adjustment tool for microscopic analysis, the universal testing machine for tensile, elongation, impact strength and hardness allows to define accurately the mechanical properties both of iron and steel castings.

The instruments allows the non-destructive testing such as ultrasound and Magnetoscope.

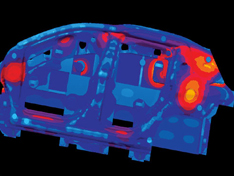

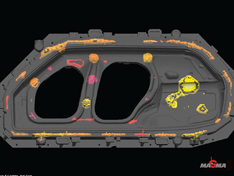

We further enhanced the activity of casting simulation using software MAGMA 5.2 and new locations for the preparation and the validation of input data.

EQUIPMENT LIST:

EQUIPMENT LIST:

- NIKON 100x-500x microscope with archive digital

- DINO-LITE 50x – 100x – 200x Portable Magnifier for surface analysis

- ERNST STE-B portable hardness

- SPECTROLAB M7 for chemical analysis of cast iron

- SPECTROMAX for chemical analysis of steel

- USM Go ADVANCED for not destructive testing

- Yoke TWST SN 24 for magnetoscope analysis

- Hoytom 150 kN for tensile (elongation and hardness)

- MAGMA 5.2 for casting simulation